Poly Copper Wire

Product Details:

- Cable Length 90 m standard; custom lengths available

- No Of Core Single Core

- Connector Type Bare wire end, suitable for lugs or connectors

- Temperature -15C to +70C operational range

- Conductor Type Single core, stranded or solid conductor

- Product Type Poly Copper Wire

- Material Copper with Polymeric Insulation

- Click to view more

X

Poly Copper Wire Product Specifications

- Single Core

- Single core, stranded or solid conductor

- -15C to +70C operational range

- Available in coils of 90 m and custom lengths

- Polyvinyl Chloride (PVC) or equivalent polymer

- Internal wiring, Power distribution, Electrical installations

- 50/60 Hz Power Frequency

- Poly Copper Wire

- Industrial and Domestic Wiring

- Varies by size; typical 1.5 mm to 6 mm

- Bare wire end, suitable for lugs or connectors

- Varies by size; commonly used in low and medium power circuits

- 90 m standard; custom lengths available

- Up to 1100 V

- Withstands standard voltage surges for household and commercial applications

- Copper with Polymeric Insulation

- Standard sizes: 0.5 mm to 6 mm

- Electrical Conduction and Insulation

- Depends on size; typically up to 30A

- Pure Copper

- Red, Yellow, Blue, Green, Black, and others

- Approx. 1.5 kg (1.5 mm², 90 m coil)

- Standard as per IS/IEC standards

- Yes, conforms to IS:694/IS:1554

- High conductivity, 99.97% pure copper

- IS:694/2010 or equivalent

- 0.7 mm to 1 mm (depends on wire size)

- Moisture and chemical resistant

- Coil packed with manufacturer sealing

- Not applicable for single core; insulation acts as sheath

Poly Copper Wire Trade Information

- All India

Product Description

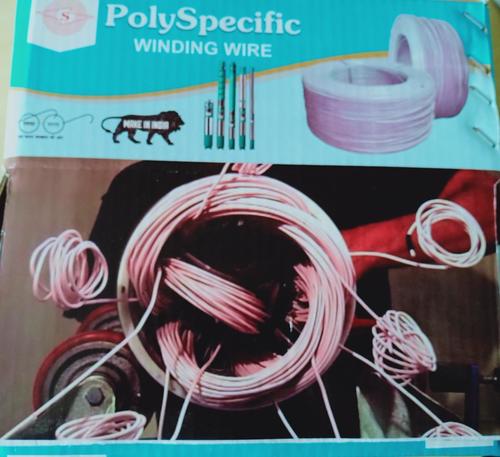

Poly copper wire with a super coating. Enamelled wire is copper wire that has a very thin insulating coating applied to it. It is employed in the production of speakers, motors, inductors, transformers, and other devices requiring tightly wound wire. The copper wire that has been enamelled is very practical since it is simple to solder. It justifies the employment of this wire type in the construction of transformers, inductors, and electromagnets. In dry settings, bare copper wire works well for purposes like electrical transmission.

High Electrical Conductivity and Safety

Crafted from 99.97% pure copper, these wires guarantee superior conductivity for optimal current flow. The insulated polyvinyl chloride sheath provides added safety, offering resistance to voltage surges, fire, moisture, and chemicals. Meeting IS:694/2010 or equivalent standards, they are suitable and dependable for both household and commercial use.

Versatile Usage for Industrial and Domestic Needs

The wires are designed for diverse applications, including internal building wiring, power distribution systems, and electrical installations in homes, offices, or industrial setups. With multiple available gauge sizes and color options, users can efficiently match circuit requirements and streamline identification tasks during installation.

FAQs of Poly Copper Wire:

Q: How does the insulation thickness affect the performance of Poly Copper Wire?

A: The insulation thickness, ranging from 0.7 mm to 1 mm depending on wire size, enhances durability and offers excellent resistance to moisture, chemicals, and fire hazards. This ensures longevity and safety in diverse installation environments.Q: What standards do these wires conform to, and why is compliance important?

A: These copper wires adhere to IS:694/2010 or IS:1554 standards, ensuring reliability, quality, and safety for use in both industrial and domestic wiring as per Indian regulations. Compliance guarantees performance under rated voltage and current specifications.Q: When should I consider using single-core, stranded or solid conductor wires?

A: Single-core wires, whether stranded or solid, are ideal for internal wiring, power distribution panels, and where flexibility (stranded) or rigidity (solid) is preferred. The selection depends on the applications mechanical and installation requirements.Q: Where can these wires be installed for safe operation?

A: They can be installed in residential, commercial, and industrial settings, including conduit wiring, panel boards, and control equipment, thanks to their insulation and flame retardant properties. Always ensure adherence to local installation guidelines for optimal safety.Q: What is the process for selecting the appropriate wire size and color for installation?

A: Wire size selection depends on current load, voltage, and application, while color coding helps identify circuit purposes. Electricians typically follow standard color codes and sizing charts as per IS/IEC standards for safe and efficient wiring.Q: How do the resistant features of these wires benefit long-term installations?

A: Moisture and chemical resistance prevents insulation breakdown over time, reducing maintenance and electrical failures. This increases the lifespan of wiring installations, especially in environments prone to dampness or chemical exposure.Q: What benefits does coil packing with manufacturer sealing offer?

A: Coil packing with manufacturer sealing protects wires from contamination or mechanical damage during transport and storage, ensuring the products integrity until installation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free